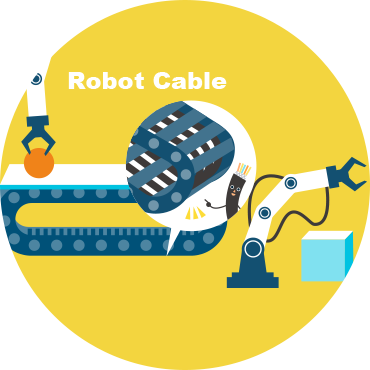

They have a top secret mission—to protect the lifelines

in the latest robots that use revolutionary AI technology and connect to the world with IoT.

Also, they must quickly and accurately send information using signals.

To accomplish such a tough mission,

they are equipped with special abilities that make the impossible possible.

The name of this special forces team is “Robot Cable.”

Let’s see what they can do.

Do you have tough environments that move repeatedly,

like the wiring for robot arms and wiring inside cable-tracks? No problem!

These cables can take on the toughest environments such as these.

These cables are made of flexible materials and have tight conductor

twist pitch and insulator pitch.

The cables are specially designed to release the stress placed

on them when they are bent.

Employing a unique conductor independently developed by Taiyo Cabletec,

it has a flexible, low-friction insulator and sheath that achieves

a high degree of bendability while allowing for easy workability.

Cables are checked for durability using bending tests,

flexing tests, folding tests, and move bending tests as shown below.

They can also be used on high-speed moving parts such as cable-tracks.

Special twisting methods invented by Taiyo Cabletec are also used

for conductors making long life possible.

for each product.

- EXT-Ⅱ

- Confirmed in-house cable-track assessment of 50 million cycles

Depending on the size, 100 million cycles confirmed

- EXT-01G

- Confirmed in-house cable-track assessment of 20 million cycles

- EXT-3D

- Confirmed in-house torsion assessment of 20 million twists

- EXT-PREM

- Confirmed in-house torsion assessment of 40 million twists

Depending on the size, 100 million twists confirmed

- TBF

- Confirmed in-house cable-track assessment of 5 million cycles

- TURBO-FLEX

- Confirmed in-house cable-track assessment of 5 million cycles

By making cables with materials that are highly heat and flame resistant,

they have a rated temperature of 105℃.

Note: Some products have a rated temperature of 80℃.

- EXT-II1

EXT-01G2

EXT-3D

EXT-PREM

TBF

TURBO-FLEX - Rated temperature: 105℃

1: The rated temperature for

EXT-II/20276 LF,

EXT-II-SB/20276 LF is 80℃

2: The rated temperature for

EXT-01G/20276 LF,

EXT-01G-SB/20276 LF is 80℃

Cable sheaths are made of highly oil resistant materials

that can keep out oil, which is found all over factory machinery,

and water.

-

Calling them heroes is an exaggeration, but the body (materials) of robot cables are not made with anything that is harmful to people, and they are safe for the global environment.

Their ultimate mission is to contribute to the future of the Earth and mankind.

-

Robot cables work in tough environments where they are required to move repeatedly and continuously, such as in the arms of robots and the internal wiring of cable-track that work in the production lines of the latest automated, unmanned factories.